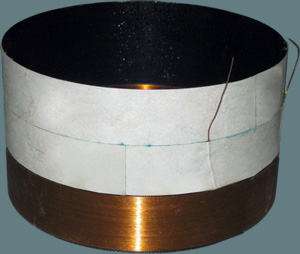

The Boxal srl Coils produces professional, high-quality fiberglass wires with aluminum and copper for speakers. The thirty-year experience in the field brought their know-how at the highest level, machinery for the construction of the coils were made internally, experience in recent years has enabled us to achieve a high performance product appreciated and valued highly.

To request info and estimates

BOXAL s.r.l.

Address

Via Maestri del Lavoro, 23

60012 - Trecastelli - AN - Italy

Phone